Here

are some key features and uses of plastic chains for barricading:

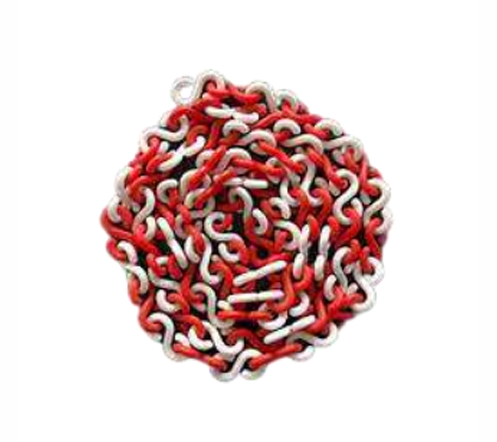

1.Material:

Plastic chains are typically made from high-density polyethylene (HDPE) or other durable

plastic materials. This makes them resistant to

weather conditions and UV radiation, ensuring a longer lifespan.

2.Link Design:

The chains are designed with interlocking links that can be easily connected and

disconnected, allowing for quick and flexible installation.

3.Visibility:

Plastic chains are available in various colors, including bright and highly visible options.

This enhances their effectiveness in creating visual

barriers and alerts.

4.Lightweight:

Plastic chains are lightweight, making them easy to handle and transport. This is especially

useful when setting up temporary barricades or

managing crowd control at events.

5.Versatility:

Plastic chains are versatile and can be used in a variety of settings, including construction

sites, parking lots, warehouses, event venues, and

more.

6.Customization:

Some plastic chain products come with accessories like S-hooks or C-hooks, allowing for easy

customization and attachment to barriers, poles,

or cones.

7.Reusable:

Plastic chains are often reusable, and their modular design allows for easy storage and reuse

for different events or situations.

8.Safety Compliance:

When used for crowd control or safety purposes, plastic chains should meet safety standards

and regulations to ensure they are effective and do

not pose a hazard.

9.Durability:

Plastic chains are designed to withstand outdoor conditions and are resistant to rust and

corrosion, making them suitable for both indoor and

outdoor use.

10.Applications:

Common applications include creating visual barriers around hazardous areas, marking off

construction zones, guiding pedestrian traffic, and

managing queues at events