Here are some key characteristics and functions of cable carriers:

1.Protection:

Cable carriers shield cables and hoses from environmental factors such as dust, dirt,

moisture, and

other contaminants. They also protect against mechanical stresses like bending, abrasion,

and torsion, helping to

extend the life of the cables.

2.Guidance:

The carrier guides the movement of cables and hoses along a predefined path, preventing

tangling or

snagging during the operation of machinery. This guidance ensures a smooth and controlled

motion.

3.Organization: Cable carriers help organize and bundle multiple cables and hoses,

preventing them from

becoming tangled or interfering with each other. This organization makes it easier to manage

and maintain the

cables.

3.Organization:

Cable carriers help organize and bundle multiple cables and hoses, preventing them from

becoming tangled or interfering with each other. This organization makes it easier to manage

and maintain the

cables.

4.Flexibility:

Cable carriers are designed to be flexible, allowing for movement in various directions. This

flexibility

is crucial for applications where the cables need to move with the machinery or equipment.

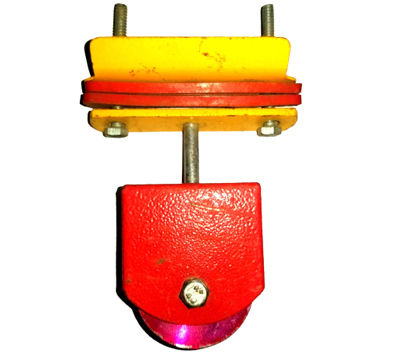

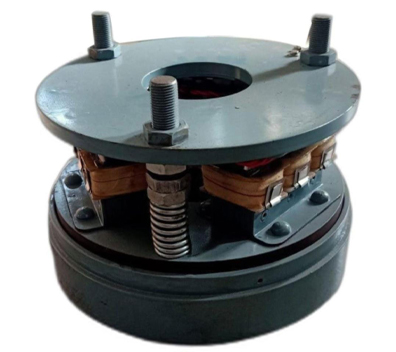

5.Materials:

Cable carriers are typically made from durable materials such as plastic or metal. The choice

of

material depends on the application's specific requirements, including factors like load

capacity, environmental

conditions, and resistance to chemicals or extreme temperatures.

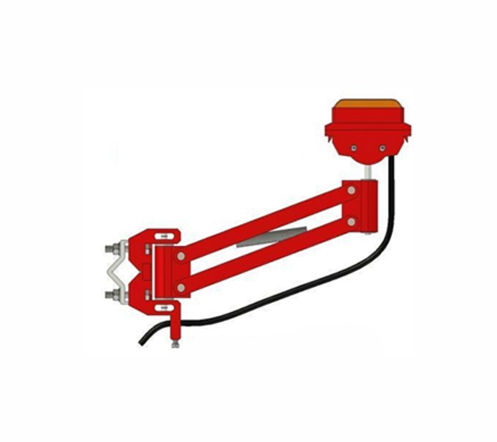

6.Mounting:

Cable carriers are mounted to the machinery or equipment, and they can be either fixed or

moving,

depending on the application. Some cable carriers are designed for vertical or horizontal

movements, while others

can handle multi-axis motion.

7.Easy Access:

Many cable carriers feature openable or easily accessible designs, allowing for convenient

installation, inspection, and maintenance of cables without the need for complete

disassembly.

Cable carriers are commonly used in a variety of industries, including manufacturing,

automation, robotics, and

material handling. They play a crucial role in ensuring the reliable and efficient operation

of machinery by protecting

and managing the cables that provide power, control signals, and communication between

different components.