Here are some key features and considerations related to wire rope slings:

1.Construction:

1. Wire Rope Material:Wire rope slings are typically made of steel wires.

The wires are often galvanized for corrosion resistance or coated for

additional protection.

2. Strands and Core:The wire rope consists of multiple strands twisted

together, and some wire ropes have a central core for added strength.

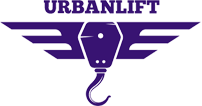

2.Types of Wire Rope Slings:

1. Single Leg Sling:Consists of a single length of wire rope with fittings

at the ends for attachment.

2. Multi-Leg Sling:Consists of multiple legs of wire rope joined at a

common fitting, providing additional lifting points.

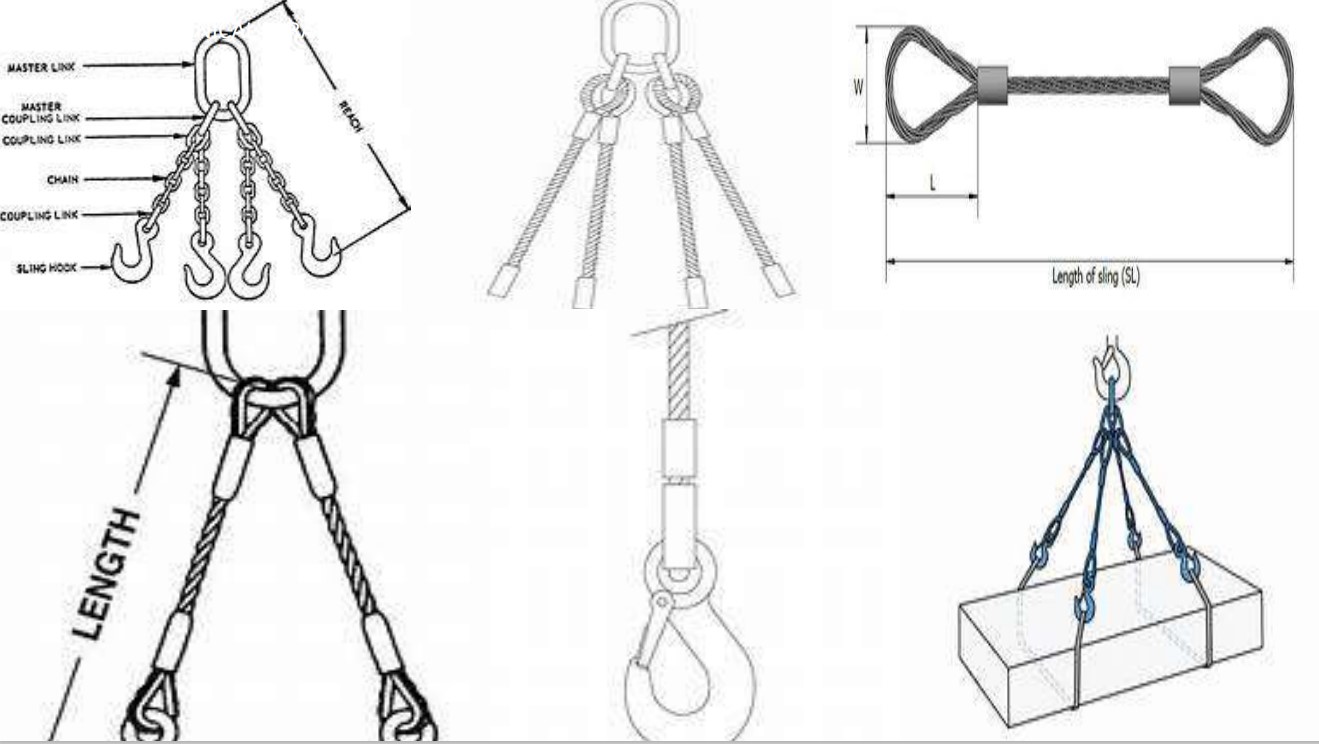

3.End Fittings:

1. Hooks:Wire rope slings often have hooks at the ends for easy attachment

to loads or lifting equipment.

2. Thimbles:Thimbles are used to protect the eyes (loops) of the wire rope

from wear and deformation.

3. Swaged or Flemish Eye:These are types of end terminations where the

wire rope is formed into an eye.

4.Capacity and Working Load Limit (WLL):

1. Rated Capacity:Wire rope slings are assigned a rated capacity based on

their size, construction, and design.

2. Working Load Limit (WLL):The maximum load that a wire rope sling is

allowed to lift under normal working conditions. It is typically a fraction of

the breaking strength of the wire rope.

5.Configuration:

1. Basket Sling:The wire rope forms a continuous loop with both ends

attached to the lifting hook.

2. Choker Sling:The wire rope is passed around the load and attached to

the hook, forming a choker configuration.

3. Vertical Hitch:The load is lifted vertically using a single leg or

multiple legs of the wire rope.

6.Inspection and Maintenance:

1. Regular Inspections:Wire rope slings should be regularly inspected for

wear, damage, or deformities. Damaged slings should be taken out of

service.

2. Proper Storage:Proper storage is essential to prevent damage to the

wire rope, such as kinking or crushing.

7.Safety Considerations:

1. Proper Rigging:Wire rope slings should be rigged properly to ensure

safe lifting.

2. Avoid Shock Loads:Sudden jerks or shock loads should be avoided, as

they can significantly impact the lifespan of the wire rope.

Wire rope slings are versatile lifting accessories that come in various

configurations to suit different lifting applications. When using wire rope

slings, it's crucial

to follow safety guidelines, inspect them regularly, and ensure proper rigging

to ensure safe and efficient lifting operations.